Catalyst Technology Overview

Our approach is to improve combustion of the hydrocarbon fuel in two ways – first by improving combustion efficiency and secondly by realigning fuel molecules called fuel reformation.

COMBUSTION EFFICIENCY

Hydrocarbon fuels are comprised of compounds that contain carbon and hydrogen atoms. In a perfect combustion setting, available oxygen would convert all the hydrogen to water while the carbon would be transformed to carbon dioxide.

Unfortunately, achieving perfect combustion is virtually impossible. In normal operating conditions in an engine there is insufficient available oxygen, leading to incomplete or partial combustion. Instead of just carbon dioxide, water, and nitrogen, an impartial combustion process produces harmful by-products like partially burned hydrocarbons called volatile organic compounds (VOCs) and oxides of nitrogen (NOx). A loss in fuel economy also occurs because not all the fuel is properly processed to produce energy.

However, the combustion process within an engine can be improved by the application of our fuel combustion technologies. These have been shown to remove hydrogen atoms and add oxygen atoms to the fuel molecules. This has the effect of helping to lower the oxygen requirements of the fuel during combustion. With lower oxygen requirements, a more complete chemical combustion takes place and more energy is produced leading to fewer harmful by-products, and better fuel economy.

FUEL REFORMATION

When fuels are first made at the refinery, the molecules are arranged in chains called Aliphatic molecules shown below left. In this arrangement the fuel will burn most efficiently and release the most energy. Quickly however, the ends of the chains join together and the molecules form rings called Aromatic molecules shown below right. These molecules burn less readily.

Our products have been shown to reform the hydrocarbon fuel molecules effectively by splitting the longer Aromatic molecules into shorter ones. This leads to an increase in Aliphatic hydrocarbons and a reduction in Aromatic hydrocarbons that results in a more controlled and complete combustion.

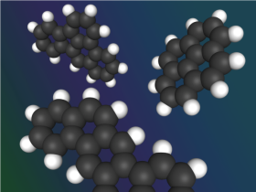

The lower set of images on the right show different gas burner flame patterns before the addition of a catalyst and above after the in-line catalyst has been installed.

Our combustion fuel catalyst also helps in the performance of the equipment. Due to the improved combustion, overall efficiency improves, and corrosion is reduced. These advantages then help improve heat transfer, reduce maintenance costs and increase overall equipment life.

This technology also contributes to the environment by reducing the amount of emissions released in the air. Noxious emissions are the result of partial combustion and combustion fuel catalysts help promote the combustion of carbon particles and condensed tar. With the reduction of soot and emissions comes not only better air quality and cleaner running equipment but also increased fuel economy.

VALIDATION