Hydrogen Technology

Background

Evidence that hydrogen could significantly improve the performance of internal combustion engines was first discovered in the United States Space Program over forty years ago.

In 1974, research on automotive applications by NASA’s Jet Propulsion Laboratory in Pasadena, California, revealed that “the addition of small amounts of hydrogen improved combustion efficiency, greatly reduced harmful emissions, improved engine torque and increased fuel economy.”

In 1977 NASA at the Lewis Research Centre carried out further extensive research. In this it was discovered that the addition of small amounts of hydrogen allowed the engine to perform normally but with less fuel. To quote from the summary of this research, flame speed during combustion in an internal combustion engine is “61 percent faster with hydrogen enrichment” and with “reduced ignition lag.” It was also found that “all emission levels decreased.”

Technology

Supplemental hydrogen is delivered by an electrolysis cell that produces hydrogen gas on demand from a supply of water.

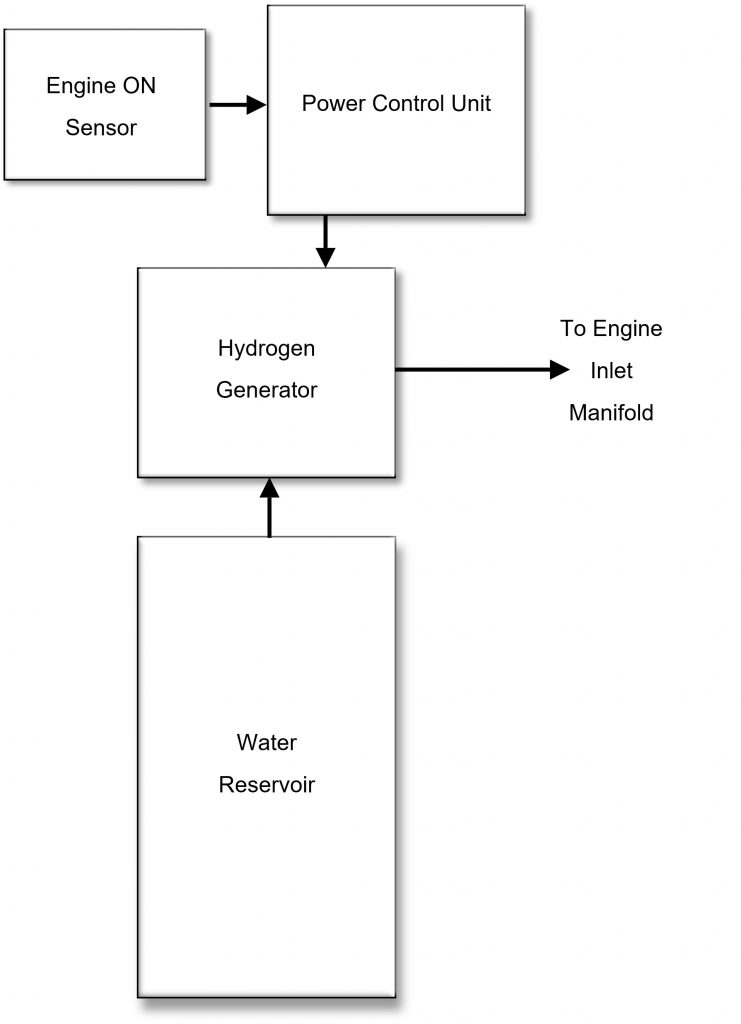

An Engine ON Sensor detects when the engine is running and this allows the Power Control Unit to deliver power to the Hydrogen Generator. This receives its supply of water from a dedicated Water Reservoir containing sensors to signal low water levels and prevent operation if the water level gets too low.

The electrical power is supplied by the engine’s alternator or an external power supply. The amount of electrical power required is negligible and has no impact on the running of the engine.

If the system runs out of water the engine will run normally as before.

The amount of hydrogen gas produced is calibrated to meet the optimum demands of the engine and the gas is delivered via the Engine Inlet manifold.

As gas is produced on demand, no gas is stored and gas tanks are not required.

As one litre of water produces many litres of hydrogen gas, the Water Reservoir does not require frequent refilling and can be topped-up as part of regular routine maintenance.